What Does Copper Foil Mean?

Wiki Article

The Definitive Guide for Copper Foil

Table of ContentsSome Ideas on Copper Foil You Should KnowThe Main Principles Of Copper Foil 9 Simple Techniques For Copper FoilThe Facts About Copper Foil RevealedCopper Foil Can Be Fun For AnyoneSome Known Facts About Copper Foil.The Basic Principles Of Copper Foil Not known Facts About Copper FoilNot known Details About Copper Foil

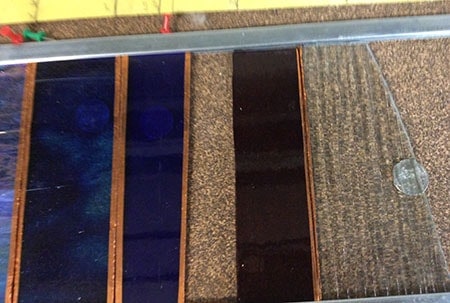

When you copper foil stained glass great deals of inquiries come up that you weren't instructed just how to deal with. Scroll down to discover an entire listing of answers to help improve your stained glass copper hindering.If you aim for the copper aluminum foil you'll be spot on. 3/16" 1/4" aluminum foil functions well for most conventional copper aluminum foil discolored glass pieces.

Copper Foil - The Facts

The Best Strategy To Use For Copper Foil

The rolls fit flawlessly and also when the lid is secured in place, it helps preserve the foil. Start hindering away from the border of a piece When you copper aluminum foil stained glass it's ideal to begin hindering away from the outside side as this produces more powerful bond. This is since the aluminum foil isn't signed up with outside edge where is is more probable to come loose.

Do you know just how to copper foil stained glass that is greatly textured? If you've attempted this you'll understand that the aluminum foil breaks as you attempt to go from high to low. Also with shallow textured glass (surges) the foil occasionally breaks as it goes throughout the surges rather than well contouring to it.

Everything about Copper Foil

Make use of a cork for kinking distinctive glass as it is softer and also provides pressure while minimizing tearing. A rubber eraser on the end of a pencil. It cleans up the aluminum foil also! This benefits croc glass as well as other very distinctive glass. Tilt the glass through the mill at an angle of 30-45 degrees, turn it and do the exact same to the various other side.Better still, you can use a to get rid of the hefty structure on the glass before hindering. Usage lined paper to aid centre the copper aluminum foil When you copper foil discolored glass by hand it can be difficult to centre the foil.

The smart Trick of Copper Foil That Nobody is Discussing

Use lined paper as a guide! When you copper aluminum foil tarnished glass you do not have to have a rough surface for the foil to stick to.You can simply mute the sharp sides off with a damp scythe rock to avoid cutting on your own as well as to prevent sharp sides cutting the foil. Occasionally when you copper aluminum foil tarnished glass the foil comes away from the side.

A Biased View of Copper Foil

Visit Your URLIf you solder as well gradually or look at the solder continuously the aluminum foil glue thaws and comes to be unstuck. It's worth bearing in mind that the glue exists to hold the foil in place until it's soldered. It does not offer to keep it on as soon as it's been heated. Try raising the width of the outside aluminum foil a tiny bit also.

If you tin the sides as opposed to creating a handmade edge. "Tinning" suggests covering them with a slim coating of solder. "Beading" is a spherical side of solder that 'clings' to the side of the stained glass and also is a lot stronger. I have visit this page a video clip on how to do a beaded edge on this page. Be gentle when cleansing and also sprucing up.

The Facts About Copper Foil Revealed

There are much more responses about copper foil not sticking below.Electrical wiring need is one of the most vital chauffeurs for digital plan choice. The Semiconductor Market Organization (SIA) (Sematech) publishes a file regularly to suggest the industry of the present and future wiring need for a range of product kinds. Table 1 reveals components of the table that was released in 1999 (copper foil).

Rumored Buzz on Copper Foil

Lower I/O remain in hand held products that compromise on efficiency to accomplish their smaller dimension. These I/O worths are leading edge applications with the largest number of I/Os. Normal applications have a lot reduced need however with time will capture up to the prominent side needs, which are 510 years ahead of the typical product.This only occurs in limited styles. The various other piece of the I/O formula is the dimension of the chip. This is generally a feature of the number of circuits are being used by the application. In Table 2, SIA (Sematech 1999) has actually defined chip dimension as a function of the kind of application. copper foil.

Copper Foil for Dummies

In this strategy, a gold or aluminum wire is bonded to a pad on the chip and afterwards looped look at here to a pad on the chip provider, which is the base for the module. A regular chip to substratum connection utilizing wire bond is kept in mind in Fig. 1. With discrete cables, their placement can not be too close or the cables will touch each other.Report this wiki page